The characteristics of:

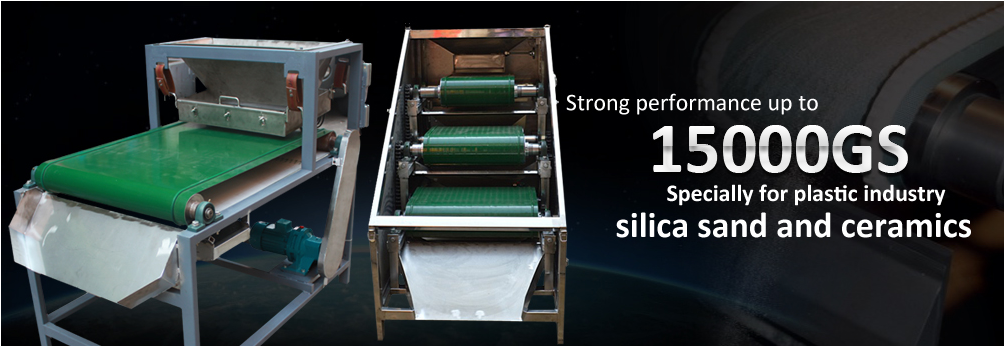

1 has the advantages of compact structure, small occupation area; the box body adopts a cold-rolled steel plate spray treatment; roller and a scraper made of stainless steel, never rust.

The 2 magnetic hub cross belt magnetic separator uniformly; by soft rubber roller extrusion dischargedirt, not cutting liquid is brought out, the grinding of mud, discharge of iron powder to keep dry, ensure the work site environment clean.

3 this product realizes the automatic separation, separation effect. The use of New magnetic roll separator machine, can reduce the number of grinding wheel correction, to improve the surface finish of the workpiece, prolong the service life of the grinding wheel and cooling fluid. At the same time, reduce the labor intensity of workers, reduce the waste of cooling liquid on environmental pollution.