Permanent magnet ceramic magnetic separator (also known as magnetic pulley), mainly applies to the following applications:

1, poor iron ore by the rough or broken in pieces after roughing, excluding the surrounding rock and other waste rock and improve quality, reduce operation under load.

2, used for Hematite reduction roasting closed-circuit operations will be not fully restore the raw ore processing, return again.

3, for use in the ceramic industry of porcelain clay mixed iron removal, improve the quality of cross belt magnetic separator products.

4, burning coal, sand casting, refractory materials and other necessities to iron-removal operation.

Magnetic Separator is used in the re-use of powdered iron removal mitochondria, etc., magnetic separator is widely used in other workshops recycling, timber, mining, ceramics, chemical, food, etc.

2015年5月29日星期五

2015年5月25日星期一

magnetic separator structure

Wet permanent cylinder type Force magnetic solution structure form for counterflow.Its feeding direction and to rounded short direction of rotation or movement of magnetic material in the opposite direction.Material feeding boxes below directly into the cylinder of the magnetic system.Non-magnetic material magnetic systems left on the floor below the discharge port.Into the material with the opposite direction of feed cylinder moves to the magnetic exhaust end, into the magnetic material collecting tanks.This equipment applicable to size 0. 6 mm strong magnetic particle collection.Such as iron-bearing dust and sludge and recovery of iron and ferric oxide medium solid recovery from heavy medium magnetic pulley separator products.

2015年5月21日星期四

Magnetic drum

Cross-belt Magnetic Separator, also known as magnetic pulley, has two kinds of permanent magnets and electromagnetic and permanent magnet drum is used, solid waste evenly on the belt conveyor, as when a magnetic drum waste, a weak magnetic or non-magnetic material under the action of centrifugal force and gravity from the belt surface;easy-cleasing magnetic traps strong magnetic force of matter being sucked in the belt.And belt to the bottom of the magnetic drum.When the belt when you leave the magnetic drum straight, fall due to magnetic field strength decreases the magnetic material in the collecting tank.This equipment is mainly used for industrial solid wastes or municipal solid waste is broken or burned before the fire.

2015年5月20日星期三

2015年5月18日星期一

Permanent Magnetic Drum Separator demagnetization solutions

Customer care to protect the work of the magnetic separator block separator in use, how to protect the magnetic blocks, the method is to a magnet coolant magnetic separators cylinder surface skin protection: the use of PVC overlay coating drum skins, Adhesive PVC coating, can greatly improve

The skin tube life. Method two fixed magnetic system of magnetic roll separators. Brushing with a glass epoxy resin ribbons, iron packing tape, stainless steel plate for the magnetic system as a whole was wrapped tests, according to test results, the use of stainless steel thickness of 0.5

Steel wrapped magnetic system. It ends with a thin stainless steel plate joints clamped and fixed with bolts, and finally bolted to adjust the degree of tension. This will not only affect the surface magnetic field of the magnetic system is small, but there is a strong enough magnetic lines of force wrapped up tight, efficient

It is remarkable. Magnetic block off the case after using this method has never been completely solved the problem fixed magnetic system. Also note that after the ceramic magnetic separator device to prevent prolonged exposure to strong sunlight, use a period of time to do the inspection equipment Measurement service.

搜索

复制

2015年5月17日星期日

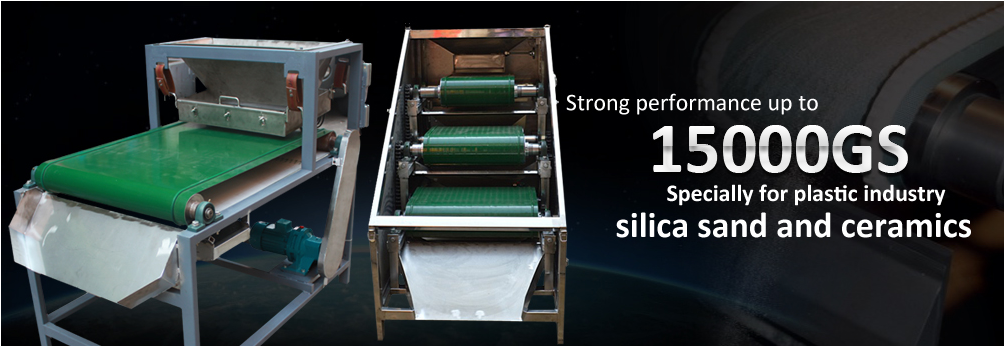

high-intensity magnetic separator

Φ 800 mm vertical ring wet High Frequency Vibrating Sieve is mainly composed of a metal ring.Vertical rotation between the two poles of the rings, the lower through a magnetic field, ore pulp by the lower ring to mine through the ring inside the circle screen grate into the ring, weak magnetic particles attached to the loop surfaces, with ring turning Ascension to the top of the magnetic field strength is very weak, concentrates by high-pressure water into the tank.Non-magnetic particles because no magnetic force through a dielectric spherical voids, flow into the tailings slot.Vertical ring wet high-intensity magnetic separator main advantage is to overcome the horizontal loop (Ping Huan) disadvantages of Automatic Glaze Separator is easily blocked, this is due to rotate with the ring in the ring to scroll across the media, undermining medium formed by magnetic orientation, played a degauss function, thereby improving the congestion.Magnetic separator test showed that the Hematite, siderite, ilmenite, chromite, wolframite, niobium tantalum minerals sodium, manganese ore, Garnet, pyroxene, amphibole, and other than susceptibility than 15x10-6 cm 3/g of fine weakly magnetic minerals separation, you can get better separation index.

2015年5月13日星期三

high-intensity magnetic separator

SHP-wet high-intensity magnetic ferrous traps is also called double disc magnetic separator, is imitating foreign Jones (JONES) strong magnetic separator manufacture of magnetic separation equipment of relevant material.

On the steel frame is equipped with two u-shaped magnetic yokes, the Department sets the standard yoke be the excitation coil, forced cooling with axial fan.Upper and lower points on the selected disc and is installed in a vertical central axis, the disc between the two opposing poles turned through u-shaped magnetic yokes on the pole and, under two separate disc constitutes a lot of closed Neodymum magnetic drum separators, and the upper and lower sorting tray is the main loop in the magnetic circuit.Disc on the perimeter of 17 sorting room, Interior fitted with multi-layer magnetic plate, inductive magnetic poles.Disc was equipped with a long pipe, below the trough, ran her in the corresponding parts of the pipe feeding the mouth.

On the steel frame is equipped with two u-shaped magnetic yokes, the Department sets the standard yoke be the excitation coil, forced cooling with axial fan.Upper and lower points on the selected disc and is installed in a vertical central axis, the disc between the two opposing poles turned through u-shaped magnetic yokes on the pole and, under two separate disc constitutes a lot of closed Neodymum magnetic drum separators, and the upper and lower sorting tray is the main loop in the magnetic circuit.Disc on the perimeter of 17 sorting room, Interior fitted with multi-layer magnetic plate, inductive magnetic poles.Disc was equipped with a long pipe, below the trough, ran her in the corresponding parts of the pipe feeding the mouth.

2015年5月9日星期六

magnetic separator

Ping Huan high-intensity ceramic magnetic separator construction characteristic is using loop-chain closed magnetic circuit the debate, copper tube coiling, low voltage and high current excitation, internal water cooling radiator cooling plate separation medium.This machine consists of ore, concentrate and ore washing device, separation rings and magnetic system, receiving device, transmission device, DC power supply, and other components.Novel magnetic structure.By concentric, radial magnetic moment inside and outside iron core and coil form.The main shaft is located in the center of the ring closed Automatic Glaze Separator circuit, magnetic line-free pass.Coil by 22x15x2 mm copper pipe wound together, each core coil turns of 33, 66 turns the iron core coil, and close to the pole.Coil cooling using water cooling, have a cooling effect, low cost, no noise and so on.

2015年5月5日星期二

Dry magnetic separator

dry drum magnetic separator is commonly used equipment equipment of iron ore and manganese ore, the prevailing strong magnetic separation mineral processing equipment.Divided into: a three-strong intensity roll dry electromagnetic separator, two cylinder two roll dry magnetic separator, a drum roll dry coolant magnetic separators;Dry magnetic separator is widely used in separating less than 2-3 of the weakly magnetic minerals and rare metals ore selection.It has a tangentbifurcation (φ = 900 mm in diameter) and double-disc (φ = 576 mm) and three (φ = 600 mm) three.Up to 8,801,440,000 a/m magnetic field strength.With φ 576 mm dual disc applications.Body of the magnetic separator is a "mountain"-shaped electromagnet with Swivel suspension induction disc composed.Disc as a dish turned upside down, pointed teeth, its diameter is larger than the ore belt width is about one-second, disc using worm gear deceleration transmission, via handwheel adjustable disc with the polar distance between the electromagnet (range 0-20) mm.In order to prevent blockage in the feed cylinder is equipped with a weak magnetic field magnetic poles, can advance in the fed to drain of strongly magnetic minerals.

2015年5月1日星期五

The structural characteristics of magnetic separator

NdFeB Rare earth Magnet is situable for the series 0.1-3mm of magnetite, pyrrhotite, roasting ore, ilmenite, and other materials wet magnetic separation, but also for coal, nonmetalliferous ore and building materials such as iron-removal operation of materials.

The machine's magnetic system, using high quality ferrite materials or compounded with rare earth magnets, the tube sheet average magnetic induction to 100~600mT.This magnetic separator has a simple structure, large capacity, easy to use, easy to maintain, and other advantages.The structural characteristics of magnetic separators: wet permanent cylinder type magnetic separator is mainly composed of a cylinder, magnetic systems, tank, drive section consists of four parts.Cylinder made of 2-3mm stainless steel plates welded tube, end cap for cast aluminum with stainless steel screws and connected to a tube.Motor through reducer, driven cylinders for rotary motion.Magnetic systems for open-magnetic system, mounted on a cylinder.

Currently the highest intensity of magnetic field magnetic separator (actual measurement) is 16500GS and is effective in the separation of limonite.Usually the high intensity magnetic separator, 150 rings can only be 13500GS, so 16500GS is a revolutionary advance.

The machine's magnetic system, using high quality ferrite materials or compounded with rare earth magnets, the tube sheet average magnetic induction to 100~600mT.This magnetic separator has a simple structure, large capacity, easy to use, easy to maintain, and other advantages.The structural characteristics of magnetic separators: wet permanent cylinder type magnetic separator is mainly composed of a cylinder, magnetic systems, tank, drive section consists of four parts.Cylinder made of 2-3mm stainless steel plates welded tube, end cap for cast aluminum with stainless steel screws and connected to a tube.Motor through reducer, driven cylinders for rotary motion.Magnetic systems for open-magnetic system, mounted on a cylinder.

Currently the highest intensity of magnetic field magnetic separator (actual measurement) is 16500GS and is effective in the separation of limonite.Usually the high intensity magnetic separator, 150 rings can only be 13500GS, so 16500GS is a revolutionary advance.

订阅:

博文 (Atom)