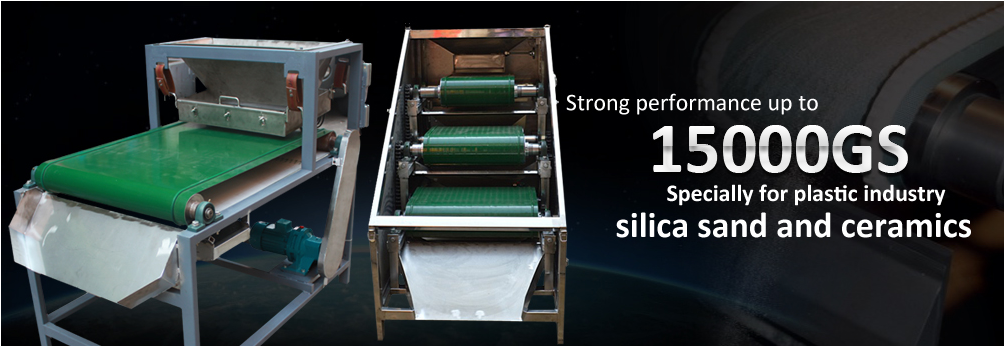

Ceramic magnetic separator

Ceramic magnetic separator features: reinforced polypropylene filter plate, filter box molded using patented technology, high strength, light weight, corrosion resistance, acid, non-toxic and tasteless; using hydraulic compression, maximum compression pressure of 14MPa, electric contact pressure gauge and automatic packing; maximum filtering pressure is 0.5MPa, to ensure the best conditions for the formation of the cake, pressure filtration; simple operation, easy maintenance, and is equipped with multiple safety devices to ensure operator safety. Application: for a variety of suspension of solid-liquid magnetic separator , wide application, used in coal, petroleum, chemical, metallurgy, medicine, light industry, food and environmental protection, textile and other industries.