FNS coolant magnetic separator beneficiation advantages:

1, according to the different ways there are downstream beneficiation, countercurrent and semi-countercurrent are three options available to customers.

2, simple structure, large capacity, high recovery rate.

3, movable tank.

4, when a part of even the students with high mineral beneficiation in the presence of particles prepared by adjusting the magnetic roller speed, can effectively improve the concentrate grade.

Magnetic Separator is used in the re-use of powdered iron removal mitochondria, etc., magnetic separator is widely used in other workshops recycling, timber, mining, ceramics, chemical, food, etc.

2015年10月31日星期六

2015年10月25日星期日

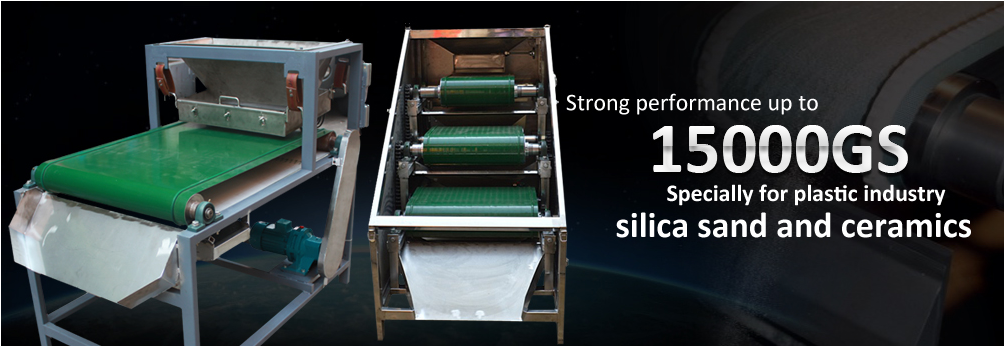

Ceramic magnetic separator for ceramics

Ceramic magnetic separator for ceramics, potassium and sodium feldspar, quartz sand, and other weakly magnetic minerals in addition to iron equipment, can be a ceramic iron impurities effectively sorting to improve the purity of the ceramic, to achieve maximum economic Ceramics value. Field equipment is generally more than 10,000 Gauss, below the permanent high-strength magnetic separation equipment. Ceramic separator divided into dry and wet magnetic separator magnetic separator in two different ways beneficiation equipment, have their own advantages.

2015年10月19日星期一

FNS coolant magnetic separator magnetic system

FNS coolant magnetic separator applies to wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials .

Wet magnetic separator magnetic system, using high-quality ferrite material or composite made with rare earth magnets, drum table the average magnetic flux density of 100 ~ 600mT. According to user needs, we can provide a variety of different table strong magnetic downstream, semi-countercurrent, countercurrent type. The separator has a simple structure, large capacity, easy to operate, easy to maintain. The equipment for the efficient use of energy saving ﹑ extremely poor iron ore and iron ore concentrate to improve the final quality of particular significance.

Wet magnetic separator magnetic system, using high-quality ferrite material or composite made with rare earth magnets, drum table the average magnetic flux density of 100 ~ 600mT. According to user needs, we can provide a variety of different table strong magnetic downstream, semi-countercurrent, countercurrent type. The separator has a simple structure, large capacity, easy to operate, easy to maintain. The equipment for the efficient use of energy saving ﹑ extremely poor iron ore and iron ore concentrate to improve the final quality of particular significance.

2015年10月13日星期二

Ceramic magnetic separators is the first of new wear-resistant materials

Ceramic magnetic separators is the first of new wear-resistant materials technology. Because of wear-resistant ceramic sheet excellent wear resistance, non-magnetic characteristics, it has other metallic and non-metallic materials incomparable superiority, and can replace austenitic stainless steel, wear-resistant rubber, wear-resistant non-metallic coatings, Widely used in iron ore processing equipment, especially on the magnetic separation equipment cylinder life than wear rubber increased by more than 5 times, improve cost performance more than twice. Superhard wear-resistant ceramic hardness HRA≥85, can reach a maximum HRA92 more, its resistance to erosion wear properties of the particles is 10 times more than domestic wear-resistant rubber, more than three times the import of rubber; even non-magnetic ceramic wear no magnetic with other wear-resistant metal materials irreplaceable superiority.

2015年10月7日星期三

FNS coolant magnetic separators of the institutions counterflow

FNS coolant magnetic separators of the institutions counterflow. It's feeding direction and the movement direction opposite the direction of rotation or circular simple magnetic tools. Material from below the magnetic system to feed tank directly into the cylinder. On the left side of the bottom plate of non-magnetic material by the magnetic system beneath the discharge port discharge. Feed material against the feed direction with the cylinder to move the discharge end of the magnetic substance, a magnetic substance into the collection tank. The device is suitable for size "0. 6 mm pre-ferromagnetic particles recovered as iron recovery and recycling dense media separation products in heavy medium iron dust and mud and iron oxide skin.

2015年10月1日星期四

Ceramic magnetic separator having good surface properties

Ceramic magnetic separator having good surface properties, can effectively improve the separation efficiency of the iron powder, iron powder to improve the taste; safe and reliable use of high strength non-magnetic adhesive, so wear-resistant ceramic magnet and metal barrel shear bond strength can be achieved the strength of 30MPa; or more, and excellent toughness, can adapt to a variety of changes in temperature and vibration conditions. Adapt to a wide range of wear-resistant ceramic is mainly used to require non-magnetic separator cylinder device, used in place of austenitic stainless steel surface wear rubber wear layer. In addition, it can be used in a variety of serious wear and tear on processing equipment, including a variety of chute, pipelines and other equipment.

订阅:

博文 (Atom)