magnetic separator is suitable for wet magnetic separation granularity below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials. Magnetic separator magnetic system, using high-quality ferrite material or rare earth magnets composite, high average magnetic induction tube table. According to user needs, we can provide a variety of different table strong magnetic downstream, semi-countercurrent, countercurrent type.It has a simple structure, large capacity, easy to operate, easy to maintain.

Magnetic Separator is used in the re-use of powdered iron removal mitochondria, etc., magnetic separator is widely used in other workshops recycling, timber, mining, ceramics, chemical, food, etc.

2015年12月29日星期二

2015年12月26日星期六

Caution Magnetic Separator

Caution magnetic separator

(A) Before use, the transmission should be added to an appropriate amount of gear oil, lubricating all the bearings.

(B) When using a magnetic system angle adjustment: that means pulling the magnetic system to adjust the high-side edge of the magnetic system to adjust to higher level trough unloading at the mine mouth.

(C) before driving should be careful to check the power lines around the gear, lubrication systems, equipment cases, confirmed normal, open the device ministries pipes, then to mine. Stop should be the first stop to the mining, gradually close the water gate. ;

(D); best choice of size of aircraft do not ask for the 60-80 mesh, the lower limit of the effective recovery of sludge is 40 microns.

(E) to determine the size of the ore concentration ore slurry flow rate of a certain amount of time to affect the size of the sorting. High concentration, slow flow, resistance, easily mixed with gangue concentrate, reduce concentrate taste, but because of the long time dressing, beneficial for recovery; the other hand, if low mineral concentration, the concentrate may be higher taste, while tailings taste It will be increased, so that the recovery rate is reduced. Reasonable feed concentration of 25-35%.

(F) a reasonable adjustment to the break up of water and concentrate ore flushing water. Break up too much water, slurry flow rate is too fast, the taste will tailings increased. Conversely, break up small water, mineral particles will not sufficiently loose and affect the separation efficiency, reduce tailings taste. Concentrate rinse water is mainly used for removing the concentrate from the drum skin, rinse water drop size should be able to ensure concentrate discharge it.

(G), please pay attention to protection.

(H) the user maintenance coolant magnetic separators process, should be strictly controlled technical indicators and work space, so as not to affect the sorting effect.

2015年12月22日星期二

Magnetic Separator Features

1, after roughing lean ore crushing or broken after exclusion of surrounding rock and other waste rock, improve quality, reduce the load on the next process.

2, the magnetic separator for hematite reduction roasting operation will be closed not fully restored ore sorting, return and then burned.

3, ceramic magnetic separator for iron removed in porcelain clay mixed in the ceramic industry, improve the quality of ceramic products.

4, burning coal, foundry sand, refractories and other lines required in addition to iron work.

2015年12月19日星期六

Coolant Separator magnetic field strength becomes weaker

Magnetic coolant separator field strength weakens its reasons: 1) the temperature is too high; 2) sun exposure; 3) acid corrosion. You can use Gauss meter. magnetic separator from the base, under the magnetic system, the cage, the magnetic system, hollow shaft, concentrate tank, gear and other components. Installed base with hollow bearing seat as a benchmark to measure the elevation and levelness. Positioned under the magnetic system to stand as a benchmark. Cage and the upper and lower magnetic gap adjustment system must be accurate, the gap deviation limit hand 0 + 1mm.

2015年12月15日星期二

Magnetic separator machine motor overheating and noise is not normal reasons

Magnetic coolant separator machine motor overheating and noise is not normal.

magnetic separator machine motor overheating and noise is not normal reasons: 1) poor or badly worn bearing lubrication; 2) fan leaves fall off or wear; 3) switch line is bad, or break run single phase; 4) voltage is too low .

2015年12月11日星期五

Coolant Separator should check and repair Monthly

Magnetic coolant separator month following parts should be checked and maintenance.

(1) must not exceed the specified drive chain wear, such as the impact of normal use should resolutely be replaced. Timely adjustment of the tightness of the transmission chain.

(2) Checking drive sprocket, linear deviation of not more than one millimeter. If the deviation should be adjusted.

(3) Check the fastening device support frame, motor, reducer, roller shaft fixing bolts.Both sides of the large cap

(4) magnetic separator, the bearing cap bolts to be checked, tightened.

(5) to conduct a comprehensive examination of the body and the drum, whether the open welding, breakage deformation and other issues.

(6) for measuring, checking lead concentrate feed weir, weir remains level.

(7) The magnetic system wrap angle inspection method is to use a welding rod, level place to concentrate the discharge weir as described suction high magnetic system, concentrate not falling, the suction system is too weak to explain the low magnetic concentrate difficult to discharge, to achieve a adsorbed magnetite powder to discharge weir, automatically from the field, successfully discharged.

2015年12月8日星期二

Features cross belt magnetic separator

cross belt magnetic separator is a magnetic separator.

Features cross belt magnetic separator is the magnetic system for the electromagnetic system and the magnetic system wrap angle is large, in order to improve the thermal and moisture by preventing the coil, filled with transformer oil inside the cylinder; cylinder speed is slow, 5 revolutions per minute, belt around the cylinder in slow motion, magnetic products are discharged by a good belt dehydration, which is heavy medium recovery and reuse is important.

2015年12月4日星期五

Classification by body shape structure and function

According to the shape of the body structure is divided into belt magnetic separator, dry magnetic separators,magnetic separator roll, disc separator, ring magnetic separator, magnetic separator and pulley cage type magnetic separator.

Mainly in the magnetic field strength, sorting media and structure type to distinguish. Weak magnetic separator is mainly used for sorting the strong magnetic minerals, such as magnetite, Chin magnetite, ferrosilicon. More industrially formerly electromagnetic magnetic system, the body shape mostly cylinder and belt. At present, many of the permanent magnetic system and cylindrical, and is widely used in the wet. Past domestic and international aspects of the strong magnetic separator sorting coarser mainly dry high intensity magnetic separation machine for sorting non-ferrous and rare minerals. Over the past decade, for sorting low grade disseminated fine grain size and mineral composition of complex weakly magnetic minerals, we have developed various forms of wet high intensity magnetic separator, such as a ring, cage, disc, most still in the experimental stage. Moderate magnetic separator is mainly used to sorting strong local oxidation of magnetic ore.

2015年12月1日星期二

What is dry magnetic separator?

magnetic separator, I believe we will not be unfamiliar. That dry magnetic separation machine, I do not know whether there are better? What is dry magnetic separator machine? What dry magnetic separator working principle and characteristics of what is it? Hereinafter, small series will share relevant knowledge dry magnetic separator with you.

dry magnetic separators is carried out sorting machinery for dry magnetic separation of magnetic minerals, with respect to wet magnetic separator to use liquid as a diluent to improve the terms of separation efficiency when sorting mineral, dry magnetic separator is required to be Sorting the mineral drying, particles can move freely between, into independent free state, otherwise it will affect the magnetic effect, and even the consequences can not be sorted.

Dry magnetic separator equipment is commonly used in iron and manganese equipment, the mainstream of the strong magnetic separator beneficiation equipment. Dry magnetic separation is carried out sorting machinery for dry magnetic separation of magnetic minerals, with respect to wet magnetic separator to use liquid as a diluent to improve the terms of separation efficiency when sorting mineral, dry magnetic separator is required to be Sorting the mineral drying, particles can move freely between, into independent free state, otherwise it will affect the magnetic effect, and even the consequences can not be sorted. Dry magnetic separator machine is suitable for wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials.

Dry magnetic separator magnetic system, using high-quality ferrite material or a composite made with rare earth magnets, drum table the average magnetic flux density of 100 ~ 600mT. The separator has a simple structure, large capacity, easy to operate, easy to maintain. Dry magnetic separator device with commotion high magnetic fields and the characteristics of the separation factor, advanced structure, light weight, reliable operation, easy maintenance. Dry magnetic separator machine is very suitable for arid regions, to save water, reduce dressing costs for ultra-poor magnetite mining and utilization has opened up a new way.

2015年11月27日星期五

Separator Operation

1. The separator must be fully checked before work properly if the ministries operating mechanism, the guide arm with a thin cotton wipe clean and press the lubricant grades oiling.

2. magnetic separator arm and headstock locking ministries, in order to operate.

3. The ceramic magnetic separator can not have obstacles within arm swing range.

4. Before opening splintered mechanical separator, magnetic separation machine table, the workpiece, fixtures, cutting tools, you must find a positive fastening.

5. Separator correct selection of spindle speed, feed rate, can not overload to use.

6. drilling beyond the table, the workpiece must be stable.

7. Magnetic Machine tools in operation and automatic feed, not allowed to change the tightening exchange rate, if the shift spindle can be completely stopped, it can take place.

8. Separator cutting tools and measuring the workpiece loading and unloading must be carried down, not allowed to directly holding the workpiece drilling, shall not wear gloves.

9. Separator work were found to have abnormal sound, you must immediately stop check troubleshooting

2015年11月24日星期二

Wet permanent drum magnetic separator

Wet permanent magnet made in the form of cylindrical magnetic separator body is counter-current. It's feeding direction and the movement direction opposite the direction of rotation or circular simple magnetic substance. Material from below the magnetic system to feed tank directly into the cylinder. On the left side of the bottom plate of non-magnetic material by the magnetic system beneath the discharge port discharge. Feed material against the feed direction with the cylinder to move the discharge end of the magnetic substance, a magnetic substance into the collection tank. The device is suitable for size "0. 6 mm pre-ferromagnetic particles recovered as iron recovery and recycling dense media separation products in heavy medium iron dust and mud and iron oxide skin.

2015年11月19日星期四

On dry magnetic separator

dry magnetic separators equipment is commonly used in iron and manganese equipment, the mainstream of the strong magnetic separator beneficiation equipment. Divided into: a three-roll tube dry high intensity magnetic separation machine, two cylinder two rollers dry magnetic separator, a barrel roll a dry magnetic separator; dry high intensity magnetic disc magnetic separator is widely used in sorting less than 2 -3 mm of weakly magnetic minerals and rare metal ores selection again. It has a single disc (diameter φ = 900 mm) Double (φ = 576 mm) of and three (φ = 600 mm) of three. Magnetic field strength up to 880-1440 kA / m. Among φ576 mm double disc used more often. The main part of magnetic separator is a "mountain" shape suspension electromagnet and the rotatable disc composed of induction. Disc like a saucer turned upside down with the tines of one of its diameter than the width of the belt to mine about sophomore points, disk using worm gear reducer, adjustable pole between the disc and the electromagnet by handwheel distance (adjustment range 0-20) mm. To prevent clogging, the ore cylinder built with a weak magnetic field, can be pre-discharge to feed the strong magnetic minerals.

2015年11月17日星期二

About Magnetic Separator

magnetic separator is one of the most extensive, highly versatile models in the industry for having a separation of the magnetic material difference. Magnetic Separator is widely used in mining, the timber industry, ceramics, chemical, food and other industries. And for the mining industry, the magnetic separator is suitable for particle size less than 50mm of manganese ore, magnetite, pyrrhotite, roasted ore, ilmenite, hematite limonite and other materials, wet or dry magnetic separation, but also with in addition to iron work in coal, non-metallic minerals, building materials and other materials. Magnetic separator magnetic system is divided into two categories, permanent magnetic separator, the more high-quality ferrite material or rare earth magnets composite made earlier times, drum magnetssurface 80 to the average magnetic induction 400mT. With the continuous development of technology, can be made into a roll-shaped separator after the magnetic field strength is increased to 1650mT, already it is the highest measured magnetic field strength.

2015年11月11日星期三

Magnetic Separator

According to the type of magnet points can be divided into: permanent magnetic separator and electromagnetic iron machine

Classified in accordance with wet ore can be divided into: iron dry, wet iron machine

Classified in accordance with the magnetic system can be divided into: dry drum magnetic separator, roll-type magnetic separator machine and roller magnetic separator magnetic separator machine and flat.

Classified according to the number of magnetic system can be divided into: single cylinder magnetic separator, binoculars and modular multi-tube magnetic separator magnetic separator.

According to mine way classification can be divided into: the upper magnetic separator to the mine, the lower magnetic separator to the mine.

Classification according to the magnetic field strength can be divided into: weak magnetic separator, magnetic separator and magnetic separator.

In accordance with the classification of magnetic system can be divided into: an open magnetic circuit dry magnetic separators, closed magnetic circuit magnetic separator.

2015年11月10日星期二

Permanent magnetic head pulley Magnetic Pulley ), mainly for the following purposes:

(also known as

1, after roughing lean ore crushing or broken after exclusion of surrounding rock and other waste rock, improve quality, reduce the load on the next process.

2 for hematite reduction roasting operation will be closed not fully restored ore sorting, return and then burned.

3, for the ceramics industry in the porcelain clay mixed iron removed to improve the quality of ceramic products.

4, burning coal, foundry sand, refractories and other lines required in addition to iron work.

2015年11月6日星期五

Features cross belt magnetic separator

Features cross belt magnetic separator is the magnetic system for the electromagnetic system and a large wrap angle magnetic system for 270 °. In order to improve the thermal and moisture by preventing the coil, the inner cylinder is filled with transformer oil; drum speed is slower, 5 revolutions per minute, the belt around the cylinder to slow motion, magnetic products are discharged by a belt excellent dehydration (magnetic tools concentration up to 65% -70%), which is heavy medium recovery and reuse is very important. Cross-belt magnetic separator production capacity, adaptability, simple structure, reliable and easy to operate, small footprint.

2015年10月31日星期六

FNS coolant magnetic separator beneficiation advantages

FNS coolant magnetic separator beneficiation advantages:

1, according to the different ways there are downstream beneficiation, countercurrent and semi-countercurrent are three options available to customers.

2, simple structure, large capacity, high recovery rate.

3, movable tank.

4, when a part of even the students with high mineral beneficiation in the presence of particles prepared by adjusting the magnetic roller speed, can effectively improve the concentrate grade.

1, according to the different ways there are downstream beneficiation, countercurrent and semi-countercurrent are three options available to customers.

2, simple structure, large capacity, high recovery rate.

3, movable tank.

4, when a part of even the students with high mineral beneficiation in the presence of particles prepared by adjusting the magnetic roller speed, can effectively improve the concentrate grade.

2015年10月25日星期日

Ceramic magnetic separator for ceramics

Ceramic magnetic separator for ceramics, potassium and sodium feldspar, quartz sand, and other weakly magnetic minerals in addition to iron equipment, can be a ceramic iron impurities effectively sorting to improve the purity of the ceramic, to achieve maximum economic Ceramics value. Field equipment is generally more than 10,000 Gauss, below the permanent high-strength magnetic separation equipment. Ceramic separator divided into dry and wet magnetic separator magnetic separator in two different ways beneficiation equipment, have their own advantages.

2015年10月19日星期一

FNS coolant magnetic separator magnetic system

FNS coolant magnetic separator applies to wet magnetic particle size below 3mm magnetite, pyrrhotite, roasted ore, ilmenite and other materials, also used in addition to iron work coal, non-metallic minerals, building materials and other materials .

Wet magnetic separator magnetic system, using high-quality ferrite material or composite made with rare earth magnets, drum table the average magnetic flux density of 100 ~ 600mT. According to user needs, we can provide a variety of different table strong magnetic downstream, semi-countercurrent, countercurrent type. The separator has a simple structure, large capacity, easy to operate, easy to maintain. The equipment for the efficient use of energy saving ﹑ extremely poor iron ore and iron ore concentrate to improve the final quality of particular significance.

Wet magnetic separator magnetic system, using high-quality ferrite material or composite made with rare earth magnets, drum table the average magnetic flux density of 100 ~ 600mT. According to user needs, we can provide a variety of different table strong magnetic downstream, semi-countercurrent, countercurrent type. The separator has a simple structure, large capacity, easy to operate, easy to maintain. The equipment for the efficient use of energy saving ﹑ extremely poor iron ore and iron ore concentrate to improve the final quality of particular significance.

2015年10月13日星期二

Ceramic magnetic separators is the first of new wear-resistant materials

Ceramic magnetic separators is the first of new wear-resistant materials technology. Because of wear-resistant ceramic sheet excellent wear resistance, non-magnetic characteristics, it has other metallic and non-metallic materials incomparable superiority, and can replace austenitic stainless steel, wear-resistant rubber, wear-resistant non-metallic coatings, Widely used in iron ore processing equipment, especially on the magnetic separation equipment cylinder life than wear rubber increased by more than 5 times, improve cost performance more than twice. Superhard wear-resistant ceramic hardness HRA≥85, can reach a maximum HRA92 more, its resistance to erosion wear properties of the particles is 10 times more than domestic wear-resistant rubber, more than three times the import of rubber; even non-magnetic ceramic wear no magnetic with other wear-resistant metal materials irreplaceable superiority.

2015年10月7日星期三

FNS coolant magnetic separators of the institutions counterflow

FNS coolant magnetic separators of the institutions counterflow. It's feeding direction and the movement direction opposite the direction of rotation or circular simple magnetic tools. Material from below the magnetic system to feed tank directly into the cylinder. On the left side of the bottom plate of non-magnetic material by the magnetic system beneath the discharge port discharge. Feed material against the feed direction with the cylinder to move the discharge end of the magnetic substance, a magnetic substance into the collection tank. The device is suitable for size "0. 6 mm pre-ferromagnetic particles recovered as iron recovery and recycling dense media separation products in heavy medium iron dust and mud and iron oxide skin.

2015年10月1日星期四

Ceramic magnetic separator having good surface properties

Ceramic magnetic separator having good surface properties, can effectively improve the separation efficiency of the iron powder, iron powder to improve the taste; safe and reliable use of high strength non-magnetic adhesive, so wear-resistant ceramic magnet and metal barrel shear bond strength can be achieved the strength of 30MPa; or more, and excellent toughness, can adapt to a variety of changes in temperature and vibration conditions. Adapt to a wide range of wear-resistant ceramic is mainly used to require non-magnetic separator cylinder device, used in place of austenitic stainless steel surface wear rubber wear layer. In addition, it can be used in a variety of serious wear and tear on processing equipment, including a variety of chute, pipelines and other equipment.

2015年9月25日星期五

FNS coolant magnetic separators is separated using super powerful magnet materials

Coolant protect the engine cooling system from rust and corrosion, it can effectively inhibit scale formation and prevent tank overheating, reduce coolant evaporation, provides lubrication for the pump thermostat and other parts. In addition, in the production process, some of the iron-containing material will fall into the cooling liquid inside, to this end, we should promptly and effectively remove the coolant inside the iron impurities to higher product purity coolant.

FNS coolant magnetic separators new structure, using high-quality magnetic materials, so that the service life of longer and farther. Coolant magnetic separator is separated using a super powerful magnet materials, low noise gear motor manufactured by separating the magnetic drum to the cooling liquid iron sucked out of the cooling liquid to keep clean. Smooth operation, low power consumption; Not only that, the use of a cooling liquid magnetic separator also greatly reduce the labor of the workers, reducing environmental pollution coolant; coolant magnetic separator excellent product quality, high performance, high environmental protection, the use of cooling liquid magnetic separator so that the plant benefits decisive surge.

FNS coolant magnetic separators new structure, using high-quality magnetic materials, so that the service life of longer and farther. Coolant magnetic separator is separated using a super powerful magnet materials, low noise gear motor manufactured by separating the magnetic drum to the cooling liquid iron sucked out of the cooling liquid to keep clean. Smooth operation, low power consumption; Not only that, the use of a cooling liquid magnetic separator also greatly reduce the labor of the workers, reducing environmental pollution coolant; coolant magnetic separator excellent product quality, high performance, high environmental protection, the use of cooling liquid magnetic separator so that the plant benefits decisive surge.

2015年9月19日星期六

Cross bandage magnetic separator works

Cross belt magnetic separator works:

When the magnetic separation equipment to work in the bottom of the conveyor belt by a magnetic separator, magnetic material elements, colored elements especially in the raw material will be attracted to the surface of the iron cleaning cartridge. Driven by the motor, iron cleaning tape will move forward, and will be driven magnetic element iron cleaning tape moving on to the appropriate friction and lower baffle effect. When the difference between the magnetic field of the magnetic element is moved, as a result, their gravity and inertia, which will drop to the bottom of the collecting bin magnetic separator, or down to another conveyor belt, is transported to the assembly area, which is self-cleaning process end.

When the magnetic separation equipment to work in the bottom of the conveyor belt by a magnetic separator, magnetic material elements, colored elements especially in the raw material will be attracted to the surface of the iron cleaning cartridge. Driven by the motor, iron cleaning tape will move forward, and will be driven magnetic element iron cleaning tape moving on to the appropriate friction and lower baffle effect. When the difference between the magnetic field of the magnetic element is moved, as a result, their gravity and inertia, which will drop to the bottom of the collecting bin magnetic separator, or down to another conveyor belt, is transported to the assembly area, which is self-cleaning process end.

2015年9月13日星期日

Coolant magnetic separation equipment Features and Benefits

FNS coolant magnetic separators continuous coolant flow and deposits included in the sale bin removal of non-ferrous materials. It is an ideal production run ferrous material cutting and grinding tools and water-based coolants, cutting oils or straight extending the life cycle of the machine and coolant. It provides improved productivity, less downtime replacing the cooling machine.

Coolant magnetic separation equipment Features and Benefits:

1, the automatic and continuous self-cleaning;

2, cost-effective and long-lasting;

3, easy to install;

4, extend tool life and coolant.

Coolant magnetic separation equipment Features and Benefits:

1, the automatic and continuous self-cleaning;

2, cost-effective and long-lasting;

3, easy to install;

4, extend tool life and coolant.

2015年9月7日星期一

Wear-resistant ceramic widely used on ceramic magnetic separator cylinder life

Wear-resistant ceramic excellent wear resistance, non-magnetic characteristics, it has other metallic and non-metallic materials incomparable superiority, can replace stainless steel, wear-resistant rubber, wear-resistant non-metallic paint, widely used in iron ore processing equipment, especially on ceramic magnetic separator cylinder life than wear rubber increased by more than 5 times, improve cost performance more than twice. Superhard wear-resistant ceramic hardness HRA≥85, can reach a maximum HRA92 more, its resistance to erosion and wear properties of the particles is more than 10 times that of domestic wear-resistant rubber, more than three times the import of rubber; even non-magnetic ceramic wear no magnetic with other wear-resistant metal materials irreplaceable superiority; high separation rates due to the ceramic magnet having super powerful magnet properties, can effectively improve the separation efficiency of the iron powder, iron powder to improve the taste; safe and reliable use of high strength non-magnetic adhesive, the bonding strength wear-resistant ceramic and metal barrel shear strength can reach 30MPa; or more, and excellent toughness, can adapt to changes in temperature and vibration conditions.

2015年9月1日星期二

Features cross straps magnetic separator

Features cross belt magnetic separator:

1, strong magnet field strength.

2, the sealing structure, the separator water, dust and corrosion.

3, low energy consumption.

4, magnetic separation equipment has high efficiency, stable performance and good flexibility.

5, easy to install and use, low maintenance costs.

6, long service life.

1, strong magnet field strength.

2, the sealing structure, the separator water, dust and corrosion.

3, low energy consumption.

4, magnetic separation equipment has high efficiency, stable performance and good flexibility.

5, easy to install and use, low maintenance costs.

6, long service life.

2015年8月27日星期四

FNS coolant magnetic separators consists of

FNS coolant magnetic separators consists of a magnetic roller, rubber roller, scraper, stainless steel tanks of several parts, suitable for removing the coolant inside the ferromagnetic impurities, in order to improve production quality, the customer is put together using a magnetic separator supporting grinder by powerful magnetic roll separators magnetic, ferromagnetic material in the liquid chips, debris separated. Scope is particularly suitable for a variety of grinders, cooling fluid lapping, drawing machine, EDM, and other processing equipment purification, purification and other fine processing machine grinder coolant.

2015年8月21日星期五

Ceramic magnetic separator features

Ceramic magnetic separator features: reinforced polypropylene filter plate magnet, magnetic coolant filters box molded using patented technology, high strength, light weight, corrosion resistance, acid and alkali, non-toxic and tasteless; hydraulic compression, the maximum clamping pressure 14MPa, and electric contact pressure gauge automatic packing; maximum filtering pressure is 0.5MPa, to ensure the best conditions for the formation of the filter cake, pressure filtration; simple operation, easy maintenance, and is equipped with multiple safety devices to ensure operator safety. Application: for a variety of solid-liquid separation suspension for a wide range, used in coal, petroleum, chemical, metallurgy, medicine, light industry, food, environmental protection, textiles and other industries.

2015年8月15日星期六

cross belt magnetic separator magnetic separation equipment

With cross belt magnetic separator magnetic separation equipment is usually suspended above the conveyor, vibrating conveyor, vibrating feeder or chute attract magnetic element, in particular a non-magnetic material colored elements for purifying material or protected crusher, milling in the next production step. Belt magnetic separator magnetic iron component cleaning with automatic cleanup to attract. Belt separator can be divided into electromagnetic separator with permanent magnetic separator and the belt. With permanent magnetic separator using rare earth permanent magnet and ferrite magnet to form its permanent magnetic system with magnetic separator and an electromagnetic field coil system formed. Continuous belt magnetic separator occasions, usually in large amounts of iron materials. Belt magnetic separator is widely used in cement, chemicals, plastics, coal, refractory materials, building materials, food and other industries.

2015年8月9日星期日

FNS cooling liquid magnetic separator has six advantages

FNS coolant magnetic separators has six advantages:

1, the transmission system and the cabinet separated for easy cleaning and maintenance;

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate;

3, can be processed containing magnetic impurities absorbing powder coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

1, the transmission system and the cabinet separated for easy cleaning and maintenance;

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate;

3, can be processed containing magnetic impurities absorbing powder coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

2015年8月3日星期一

Metal cutting machine tool coolant in ferromagnetic material separation

Metal cutting machine tool coolant (cutting oil and emulsions) in ferromagnetic material separation. Through a strong performance magnets, the liquid ferromagnetic chips, debris separated. Works by cutting fluid into the box, when the liquid flows through the magnetic hub under the arc channel, the liquid portion of the ferromagnetic material and inclusions are strong adsorption of magnetic roller, the cleaning liquid flows out from the outlet. Stop rotation of the hub, Cots extruded material in the residue, scraper collect adsorbate complete the automatic separation process. Maintaining a clean cutting fluid to improve the processing performance and tool life, while reducing machine tool cooling system failure rate.

2015年7月28日星期二

Using coolant magnetic separators clean-up coolant

Just with a good initial coolant is pure, if the external particles into the coolant necessary to reduce the cutting tool (such as wheel) of life, and bring a very negative impact to the machining quality. It can be expected to think, cutting down on parts from high temperature metal particles, when in contact with the cooling liquid will harden; when it falls between the grinding wheel and the workpiece, the hard particles will draw scar on the part surface.

Using coolant magnetic separators clean-up coolant of treatment, this way less investment, without changing the site water tank, coolant cycle extended, improve workpiece finish. Magnetic separation equipment automatic suction slag, slag automatically, without human intervention.

Using coolant magnetic separators clean-up coolant of treatment, this way less investment, without changing the site water tank, coolant cycle extended, improve workpiece finish. Magnetic separation equipment automatic suction slag, slag automatically, without human intervention.

2015年7月17日星期五

Coolant magnetic separator for grinding machines

Coolant magnetic separator for grinding machines and other machine tool coolant (cutting oil or emulsion industry liquid) purification. By separating the magnetic drum to the cooling liquid iron sucked out of the cooling liquid to keep clean, automatic separation. Thereby enhancing the quality of processed products, reduce costs and improve productivity. Using a magnetic separator to reduce the number of grinding wheel, improving the surface smoothness of the workpiece, extend the life of the grinding wheel and coolant. Especially suitable for all kinds of grinder, coolant lapping, drawing machine, EDM, and other processing equipment purification, purification and other fine processing machine grinder coolant.

2015年7月14日星期二

coolant magnetic separators protect the engine cooling system

Coolant dedicated coolant magnetic separators protect the engine cooling system from rust and corrosion, magnetic roller can effectively inhibit scale formation and prevent tank overheating, reduce coolant evaporation, provides lubrication for the pump thermostat and other parts. In addition, in the production process, some of the iron-containing material will fall into the cooling liquid inside, to this end, we should promptly and effectively remove the coolant inside the iron impurities to higher product purity coolant.

2015年7月11日星期六

Coolant magnetic separator has six advantages

Coolant magnetic separators has six advantages:

1, the transmission system and the cabinet separated for easy cleaning and maintenance.

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate.

3, can be processed containing magnetic impurities absorbing powder separator coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

1, the transmission system and the cabinet separated for easy cleaning and maintenance.

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate.

3, can be processed containing magnetic impurities absorbing powder separator coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

2015年7月4日星期六

Coolant magnetic separator features

Coolant magnetic separators features:

1, the transmission system and the cabinet separated for easy cleaning and maintenance.

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate.

3, can be processed containing magnetic impurities absorbing powder coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

1, the transmission system and the cabinet separated for easy cleaning and maintenance.

2, magnetic roller magnetizing uniform, isolated debris, iron sulfate.

3, can be processed containing magnetic impurities absorbing powder coolant;

4, the magnetic field generated by a large, large stainless steel magnetic roller absorption area, good separation;

5, simple appearance, compact structure, smooth operation, low noise, low power consumption;

6, small, easy to install, according to the machine specific space design and manufacturing.

2015年6月27日星期六

Coolant magnetic separator using

Coolant magnetic separators is separated using a sophisticated magnetic materials, low noise gear motor manufactured by separating the magnetic drum to the cooling liquid iron sucked out of the cooling liquid to keep clean. Smooth operation, low power consumption; Not only that, the use of a cooling liquid magnetic separator also greatly reduce the labor of the workers, reducing environmental pollution coolant; coolant magnetic separator excellent product quality, high performance, high environmental protection, the use of cooling liquid magnetic separator so that the plant benefits decisive surge.

2015年6月20日星期六

Cutting oil or emulsion industry liquid

Machine tool coolant (cutting oil or emulsion industry liquid), after repeated use black iron content becomes too high, the quality of the coolant big discount, after a long study of the company's technical staff, to create a new generation of magnetic splitter, coolant magnetic separators magnetic iron filings to the coolant sucked out of the cooling liquid to keep clean. Using a magnetic separator to reduce the number of grinding wheel, improving the surface smoothness of the workpiece, extend the life of the grinding wheel and coolant, using a magnetic separation equipment year cost saving enough to buy several splitters, while reducing labor intensity, reduce coolant contamination of the environment.

2015年6月13日星期六

Analytical devices must explain why the magnetic separator to the mine size size

First, the main target of magnetic pulley separator equipment is hematite, limonite, mirror iron ore, manganese ore, nickel ore, ilmenite and other minerals magnetic separation, but also for iron coal, non-metallic minerals, building materials and other materials operations. For these objects, the direct feed size Effect of neodymium magnetic drum separators magnetic effect.

For most ores, the degree of separation marks ore monomer that is the size of the magnetic particles and gangue mineral particle separation of coarse or fine ore particle size. If you give into small ore particle size, indicating a high degree of mineral monomer separation, can be satisfied with the sorting Indicators; if the particle size of ore into fairly thick, indicating mineral insufficient dissociation, monomer separation is not high, opposite the living body that is more magnetic particles and gangue is still considerable parts together. Because of the living body also has considerable magnetic

For most ores, the degree of separation marks ore monomer that is the size of the magnetic particles and gangue mineral particle separation of coarse or fine ore particle size. If you give into small ore particle size, indicating a high degree of mineral monomer separation, can be satisfied with the sorting Indicators; if the particle size of ore into fairly thick, indicating mineral insufficient dissociation, monomer separation is not high, opposite the living body that is more magnetic particles and gangue is still considerable parts together. Because of the living body also has considerable magnetic

Sorting can choose up to a considerable part of that lower grade ore. Therefore, the requirements for the mineral separator must be sufficiently achieved monomer separation. For coarse-grained disseminated ore and gangue minerals as long as reached monomer separation on the line, do not

Certain size too small. Such ore sometimes coarse granularity although some, but not low quality sorting, the main reason is due to disseminated ore coarse granularity, grinding to a certain extent useful minerals and gangue separated.

From the above description, you can learn to directly affect the size of the ore particle size magnetic separator magnetic effect, influence the level of concentrate grade. Appropriate feed size, you can get a higher concentrate feed size too big but not conducive separator Sorting equipment.

From the above description, you can learn to directly affect the size of the ore particle size magnetic separator magnetic effect, influence the level of concentrate grade. Appropriate feed size, you can get a higher concentrate feed size too big but not conducive separator Sorting equipment.

搜索

复制

2015年6月10日星期三

Install magnetic separator block first we need to understand the material and performance magnetic separator block.

magnetic roll separators block the choice of materials are usually made of two materials. One is strontium ferrite, of the formula (SrO • nFe2O3), the other is barium ferrite, of the formula (BaO • nFe2O3) and magnetic pole pieces from NdFeB magnetic material and

Iron, ferrite magnets, alnico magnets, SmCo magnets four categories. We all know that the most important component is the belt type magnetic roll separators magnet material, magnetic material determines the quality of its performance characteristics. NdFeB magnets: NdFeB is found in the Commercialization

The highest performance magnets, known as magnetic king, have extremely high magnetic its biggest energy product (BHmax) higher than the ferrite (Ferrite) more than 10 times. Machining performance itself is also very good. Operating temperature up to 200 ° CDegrees. And its hard, stable performance, good price, so its application is extremely broad. But because of its chemical activity is very strong, it must deal with its surface coating. (E.g. plating Zn, Ni, electrophoresis, passivation, etc.). Ferrite magnets:

The main raw materials, including ferrite BaFe12O19 and SrFe12O19. Made of ceramic technology by law, texture rather hard, is a brittle material, since the ferrite magnets have good temperature resistance, low cost, moderate performance, has become the most

A wide range of permanent magnets. Alnico Magnet: Alnico is an alloy of aluminum, nickel, cobalt, iron and other trace metal elements. Casting process can be processed into different sizes and shapes, very good processability. Cast Alnico

Permanent magnet has a low reversible temperature coefficient, working temperature up to 600 degrees Celsius. Alnico magnet products are widely used in various instruments and other applications. Samarium cobalt magnets (SmCo) divided according to the different components and SmCo5 Sm2Co17. Since samarium cobalt materials are expensive and their development is limited. Samarium cobalt magnets (SmCo) as a rare earth permanent magnet, not only has a higher energy product (14-28MGOe), reliable coercive force and excellent temperature characteristics. And NdFeB Compared magnet, samarium cobalt magnets is more suited for operation in high temperature environments.

搜索

复制

2015年6月7日星期日

Select a good piece of material magnetic separator magnetic next block installation work

magnetic separator for quartz sand block with stainless steel bolts mounted on the yoke plate, extending cylinder axis of the yoke, the shaft is fixed crank arm. Pulling the crank arm angle magnetic system can be adjusted, the adjustment lever can be fixed after appropriate. Work area with stainless steel tank

Other parts of manufacturing, chassis and tank with ordinary steel welding.

搜索

复制

2015年6月4日星期四

How magnet separator is installed and measure the magnetic field strength

Install magnetic separator magnetic separator block is producing significant technical, magnet installation will determine the success of a key magnetic separator to work effectively. How to install safety magnet magnetic separator slurry separators manufacturer also many concerns, magnetic blocks

Determining the distribution field equipment, the size of the magnetic field strength. How to install magnetic separator block we have mentioned in the previous article, the simple explanation is that recycling cross belt magnetic separator with stainless steel bolts installed on the floor of the yoke, the yoke of the shaft extension tube outer, Shaft crank arm is fixed. Pulling the crank arm angle magnetic system can be adjusted, the adjustment lever can be fixed after appropriate. Work area with stainless steel tank manufacture, chassis and other parts of the tank with ordinary steel welding.

搜索

复制

2015年6月1日星期一

Magnetic separator block demagnetization reason

1, when the magnetic roll separator for plastics factory technical force some manufacturers incomplete, improper circuit design, resulting in demagnetization.

2, when the magnetic drum magnetic blocks Mifengbuyan cause corrosion oxidation.

3, the magnetic material of poor block itself, using a certain time demagnetization serious.

4, magnetic separator for ceramic industry poor working conditions, and the drum friction material temperature, causing the temperature of the magnet close to the magnet demagnetization demagnetization.

5, the initial thin magnet design, low coercivity demagnetization caused a certain time.

2, when the magnetic drum magnetic blocks Mifengbuyan cause corrosion oxidation.

3, the magnetic material of poor block itself, using a certain time demagnetization serious.

4, magnetic separator for ceramic industry poor working conditions, and the drum friction material temperature, causing the temperature of the magnet close to the magnet demagnetization demagnetization.

5, the initial thin magnet design, low coercivity demagnetization caused a certain time.

搜索

复制

2015年5月29日星期五

Magnetic separator drum performance

Permanent magnet ceramic magnetic separator (also known as magnetic pulley), mainly applies to the following applications:

1, poor iron ore by the rough or broken in pieces after roughing, excluding the surrounding rock and other waste rock and improve quality, reduce operation under load.

2, used for Hematite reduction roasting closed-circuit operations will be not fully restore the raw ore processing, return again.

3, for use in the ceramic industry of porcelain clay mixed iron removal, improve the quality of cross belt magnetic separator products.

4, burning coal, sand casting, refractory materials and other necessities to iron-removal operation.

1, poor iron ore by the rough or broken in pieces after roughing, excluding the surrounding rock and other waste rock and improve quality, reduce operation under load.

2, used for Hematite reduction roasting closed-circuit operations will be not fully restore the raw ore processing, return again.

3, for use in the ceramic industry of porcelain clay mixed iron removal, improve the quality of cross belt magnetic separator products.

4, burning coal, sand casting, refractory materials and other necessities to iron-removal operation.

2015年5月25日星期一

magnetic separator structure

Wet permanent cylinder type Force magnetic solution structure form for counterflow.Its feeding direction and to rounded short direction of rotation or movement of magnetic material in the opposite direction.Material feeding boxes below directly into the cylinder of the magnetic system.Non-magnetic material magnetic systems left on the floor below the discharge port.Into the material with the opposite direction of feed cylinder moves to the magnetic exhaust end, into the magnetic material collecting tanks.This equipment applicable to size 0. 6 mm strong magnetic particle collection.Such as iron-bearing dust and sludge and recovery of iron and ferric oxide medium solid recovery from heavy medium magnetic pulley separator products.

2015年5月21日星期四

Magnetic drum

Cross-belt Magnetic Separator, also known as magnetic pulley, has two kinds of permanent magnets and electromagnetic and permanent magnet drum is used, solid waste evenly on the belt conveyor, as when a magnetic drum waste, a weak magnetic or non-magnetic material under the action of centrifugal force and gravity from the belt surface;easy-cleasing magnetic traps strong magnetic force of matter being sucked in the belt.And belt to the bottom of the magnetic drum.When the belt when you leave the magnetic drum straight, fall due to magnetic field strength decreases the magnetic material in the collecting tank.This equipment is mainly used for industrial solid wastes or municipal solid waste is broken or burned before the fire.

2015年5月20日星期三

2015年5月18日星期一

Permanent Magnetic Drum Separator demagnetization solutions

Customer care to protect the work of the magnetic separator block separator in use, how to protect the magnetic blocks, the method is to a magnet coolant magnetic separators cylinder surface skin protection: the use of PVC overlay coating drum skins, Adhesive PVC coating, can greatly improve

The skin tube life. Method two fixed magnetic system of magnetic roll separators. Brushing with a glass epoxy resin ribbons, iron packing tape, stainless steel plate for the magnetic system as a whole was wrapped tests, according to test results, the use of stainless steel thickness of 0.5

Steel wrapped magnetic system. It ends with a thin stainless steel plate joints clamped and fixed with bolts, and finally bolted to adjust the degree of tension. This will not only affect the surface magnetic field of the magnetic system is small, but there is a strong enough magnetic lines of force wrapped up tight, efficient

It is remarkable. Magnetic block off the case after using this method has never been completely solved the problem fixed magnetic system. Also note that after the ceramic magnetic separator device to prevent prolonged exposure to strong sunlight, use a period of time to do the inspection equipment Measurement service.

搜索

复制

2015年5月17日星期日

high-intensity magnetic separator

Φ 800 mm vertical ring wet High Frequency Vibrating Sieve is mainly composed of a metal ring.Vertical rotation between the two poles of the rings, the lower through a magnetic field, ore pulp by the lower ring to mine through the ring inside the circle screen grate into the ring, weak magnetic particles attached to the loop surfaces, with ring turning Ascension to the top of the magnetic field strength is very weak, concentrates by high-pressure water into the tank.Non-magnetic particles because no magnetic force through a dielectric spherical voids, flow into the tailings slot.Vertical ring wet high-intensity magnetic separator main advantage is to overcome the horizontal loop (Ping Huan) disadvantages of Automatic Glaze Separator is easily blocked, this is due to rotate with the ring in the ring to scroll across the media, undermining medium formed by magnetic orientation, played a degauss function, thereby improving the congestion.Magnetic separator test showed that the Hematite, siderite, ilmenite, chromite, wolframite, niobium tantalum minerals sodium, manganese ore, Garnet, pyroxene, amphibole, and other than susceptibility than 15x10-6 cm 3/g of fine weakly magnetic minerals separation, you can get better separation index.

2015年5月13日星期三

high-intensity magnetic separator

SHP-wet high-intensity magnetic ferrous traps is also called double disc magnetic separator, is imitating foreign Jones (JONES) strong magnetic separator manufacture of magnetic separation equipment of relevant material.

On the steel frame is equipped with two u-shaped magnetic yokes, the Department sets the standard yoke be the excitation coil, forced cooling with axial fan.Upper and lower points on the selected disc and is installed in a vertical central axis, the disc between the two opposing poles turned through u-shaped magnetic yokes on the pole and, under two separate disc constitutes a lot of closed Neodymum magnetic drum separators, and the upper and lower sorting tray is the main loop in the magnetic circuit.Disc on the perimeter of 17 sorting room, Interior fitted with multi-layer magnetic plate, inductive magnetic poles.Disc was equipped with a long pipe, below the trough, ran her in the corresponding parts of the pipe feeding the mouth.

On the steel frame is equipped with two u-shaped magnetic yokes, the Department sets the standard yoke be the excitation coil, forced cooling with axial fan.Upper and lower points on the selected disc and is installed in a vertical central axis, the disc between the two opposing poles turned through u-shaped magnetic yokes on the pole and, under two separate disc constitutes a lot of closed Neodymum magnetic drum separators, and the upper and lower sorting tray is the main loop in the magnetic circuit.Disc on the perimeter of 17 sorting room, Interior fitted with multi-layer magnetic plate, inductive magnetic poles.Disc was equipped with a long pipe, below the trough, ran her in the corresponding parts of the pipe feeding the mouth.

2015年5月9日星期六

magnetic separator

Ping Huan high-intensity ceramic magnetic separator construction characteristic is using loop-chain closed magnetic circuit the debate, copper tube coiling, low voltage and high current excitation, internal water cooling radiator cooling plate separation medium.This machine consists of ore, concentrate and ore washing device, separation rings and magnetic system, receiving device, transmission device, DC power supply, and other components.Novel magnetic structure.By concentric, radial magnetic moment inside and outside iron core and coil form.The main shaft is located in the center of the ring closed Automatic Glaze Separator circuit, magnetic line-free pass.Coil by 22x15x2 mm copper pipe wound together, each core coil turns of 33, 66 turns the iron core coil, and close to the pole.Coil cooling using water cooling, have a cooling effect, low cost, no noise and so on.

2015年5月5日星期二

Dry magnetic separator

dry drum magnetic separator is commonly used equipment equipment of iron ore and manganese ore, the prevailing strong magnetic separation mineral processing equipment.Divided into: a three-strong intensity roll dry electromagnetic separator, two cylinder two roll dry magnetic separator, a drum roll dry coolant magnetic separators;Dry magnetic separator is widely used in separating less than 2-3 of the weakly magnetic minerals and rare metals ore selection.It has a tangentbifurcation (φ = 900 mm in diameter) and double-disc (φ = 576 mm) and three (φ = 600 mm) three.Up to 8,801,440,000 a/m magnetic field strength.With φ 576 mm dual disc applications.Body of the magnetic separator is a "mountain"-shaped electromagnet with Swivel suspension induction disc composed.Disc as a dish turned upside down, pointed teeth, its diameter is larger than the ore belt width is about one-second, disc using worm gear deceleration transmission, via handwheel adjustable disc with the polar distance between the electromagnet (range 0-20) mm.In order to prevent blockage in the feed cylinder is equipped with a weak magnetic field magnetic poles, can advance in the fed to drain of strongly magnetic minerals.

2015年5月1日星期五

The structural characteristics of magnetic separator

NdFeB Rare earth Magnet is situable for the series 0.1-3mm of magnetite, pyrrhotite, roasting ore, ilmenite, and other materials wet magnetic separation, but also for coal, nonmetalliferous ore and building materials such as iron-removal operation of materials.

The machine's magnetic system, using high quality ferrite materials or compounded with rare earth magnets, the tube sheet average magnetic induction to 100~600mT.This magnetic separator has a simple structure, large capacity, easy to use, easy to maintain, and other advantages.The structural characteristics of magnetic separators: wet permanent cylinder type magnetic separator is mainly composed of a cylinder, magnetic systems, tank, drive section consists of four parts.Cylinder made of 2-3mm stainless steel plates welded tube, end cap for cast aluminum with stainless steel screws and connected to a tube.Motor through reducer, driven cylinders for rotary motion.Magnetic systems for open-magnetic system, mounted on a cylinder.

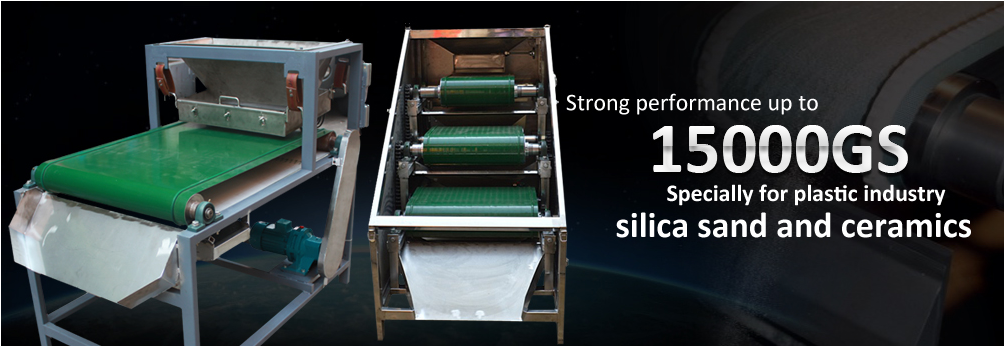

Currently the highest intensity of magnetic field magnetic separator (actual measurement) is 16500GS and is effective in the separation of limonite.Usually the high intensity magnetic separator, 150 rings can only be 13500GS, so 16500GS is a revolutionary advance.

The machine's magnetic system, using high quality ferrite materials or compounded with rare earth magnets, the tube sheet average magnetic induction to 100~600mT.This magnetic separator has a simple structure, large capacity, easy to use, easy to maintain, and other advantages.The structural characteristics of magnetic separators: wet permanent cylinder type magnetic separator is mainly composed of a cylinder, magnetic systems, tank, drive section consists of four parts.Cylinder made of 2-3mm stainless steel plates welded tube, end cap for cast aluminum with stainless steel screws and connected to a tube.Motor through reducer, driven cylinders for rotary motion.Magnetic systems for open-magnetic system, mounted on a cylinder.

Currently the highest intensity of magnetic field magnetic separator (actual measurement) is 16500GS and is effective in the separation of limonite.Usually the high intensity magnetic separator, 150 rings can only be 13500GS, so 16500GS is a revolutionary advance.

2015年4月27日星期一

Working principle of magnetic separator

After the pulp is feed tank flows into the tank, spray in feeding under the action of water currents and particles diffuse into the tank to the mining area.Effect of the magnetic field, magnetic particles of Dry drum magnetic separator agglomeration forming "magnetic" or "flux", "magnetic" or "flux" magnetic force in the pulp, and moving toward the poles and are adsorbed on the cylinder.Due to pole of polar along cylinder rotating direction is alternating arranged of, and in work Shi fixed not moving, "magnetic mission" or "magnetic chain" in with cylinder rotating Shi, due to pole alternating and produced magnetic mixing phenomenon, was inclusions in "magnetic mission" or "magnetic chain" in the of gangue, non-magnetic mineral in flip in the shedding down, eventually was sucking in cylinder surface of "magnetic mission" or "cross belt magnetic separator chain" that is fine

mine.Concentrate with the cylinder turned to edge magnetic magnetic system the most weakness, dumping was unloading hoses flush current action to concentrate tank, if is the magnetic roller, brush roll for dumping was carried out.Non-magnetic or weakly magnetic minerals are left outside in the pulp slurry discharge trough, which is tailing.

mine.Concentrate with the cylinder turned to edge magnetic magnetic system the most weakness, dumping was unloading hoses flush current action to concentrate tank, if is the magnetic roller, brush roll for dumping was carried out.Non-magnetic or weakly magnetic minerals are left outside in the pulp slurry discharge trough, which is tailing.

2015年3月25日星期三

Ceramic magnetic separator

Ceramic magnetic separator

Ceramic magnetic separator features: reinforced polypropylene filter plate, filter box molded using patented technology, high strength, light weight, corrosion resistance, acid, non-toxic and tasteless; using hydraulic compression, maximum compression pressure of 14MPa, electric contact pressure gauge and automatic packing; maximum filtering pressure is 0.5MPa, to ensure the best conditions for the formation of the cake, pressure filtration; simple operation, easy maintenance, and is equipped with multiple safety devices to ensure operator safety. Application: for a variety of suspension of solid-liquid magnetic separator , wide application, used in coal, petroleum, chemical, metallurgy, medicine, light industry, food and environmental protection, textile and other industries.

2015年3月21日星期六

Ceramic magnetic separator

Ceramic magnetic separator

Currently applied in the form of a grid-type separator cross belt magnetic separator (box-type grille), rotary grill separator, magnetic separator flow trough, mainly used in food processing, ceramics, chemicals, lithium battery materials, carbon black, flame retardants, plastics and other industries, for sorting, to iron impurities in the material, play to improve the purity of the material, to protect the downstream production line processing equipment.

With the current socio-economic development, people pay more attention to quality and safety. Grille Separators increasingly widespread application.

2015年3月17日星期二

Magnetic Tool Bar

Magnetic Tool Bar

Magnetic separator according to different sources into electromagnetic separator and permanent magnetic Tool Bar is a lump or powder material used to remove iron in iron miscellaneous equipment. Electromagnetic separator is essentially a DC electromagnet, which generates a strong magnetic field magnetic coil is energized during the non-magnetic material in the iron pick up. Permanent magnetic separator is a high coercivity, high remanence NdFeB rare earth magnetic materials and magnetic ferrite composition source to form a strong magnetic field for ferromagnetic debris sucked, the whole no electricity, no power . Magnetic filter bars in cement plants and more to protect the raw materials used clinker crushing machine, roller press, vertical mill, ball mill, such as packaging machines and grinding system. The raw material used to remove iron debris, grinding equipment to protect the safe operation and reduce the failure rate. Glass, ceramics factory raw material used to remove more impurities of iron and iron powder, to protect and improve the quality of glass crushing equipment grades. In the brick used for crusher, roller machine, brick machine iron protection.

2015年3月13日星期五

Strong magnet uses and characteristics

Strong magnet uses and characteristics

2015年3月9日星期一

Coolant magnetic separators

Coolant magnetic separators

2015年3月4日星期三

cross belt magnetic separator

cross belt magnetic separator

Separators are mainly used to remove the mixed stream from ferromagnetic material, such as iron, iron, nails, etc., or be recycled to prevent crushers, grinders and other machinery and equipment damage, can also prevent the belt conveyor by longitudinal tear.There are two kinds of cross belt magnetic separator, according to the structure and use of separable suspension, belt, magnetic roller, wet, vibration and so on. By the magnetic field strength, can be divided into general and powerful magnetic separator magnetic separator. Magnetic drum were introduced in dry strong magnet section. Originally, the main electromagnetic separator, in recent years, especially with the ilmenite boron permanent magnet materials development and application of magnetic material, permanent magnetic separator rapid development, performance has been improved to become the development direction Separators .

订阅:

博文 (Atom)